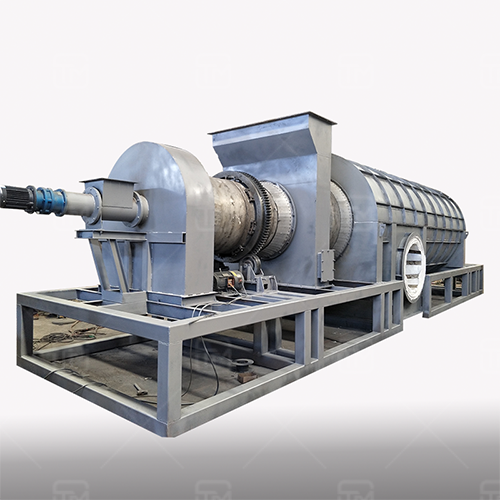

Biochar Making Machine

The traditional carbonization method can not realize continuous carbonization, resulting in low economic benefit; And the carbonization process will release a lot of soot, causing air pollution, which is not in line with the national environmental protection policy.

In view of the above situation,Tomings Machinery has devoted itself to research and development and produced an environmentally friendly and continuously working smokeless charring machine. The new continuous smokeless carbonizing machine truly realizes the multi-purpose of one machine, which can be used to carbonize hemp rods, sawdust, straw and other biomass, and can also carbonize sludge and household waste, the whole smokeless and pollution-free, in line with the national environmental protection policy.

The Range Of Materials

All kinds of waste biomass: straw, rice husk, hemp stalk, wood chips, bark, bamboo chips, bamboo powder, tree branches, coconut shell, walnut shell, palm shell, peanut shell, date stone, peel, ox bone, coffee grounds, pine cone, etc.

All kinds of garbage and sludge: domestic waste, paper mill waste, municipal sludge, river sludge, industrial sludge, printing and dyeing sludge, etc.

Chemical lignite quality improvement: carbonization of active coke, charcoal, magnesium oxide, sodium oxide and other materials.

Technical Details

| Model | TTH-0812 | TTH-1015 | TTH-1218 | TTH-1320 |

| Capacity | 500kg/h | 0.8-1 Ton/h | 1.5-2 Tons/h | 2.5-3 Tons |

| Diameter | Φ800 | Φ1000 | Φ1300 | Φ1700/h |

| Heating | Charcoal,Wood,diesel,Natural Gas,LPG, Biomass, etc | |||

| Power | 40kw/h | 55kw/h | 60kw/h | 72kw/h |

| Cooling Method | Recycling Water Cooling | |||

| Life | 5-8 Years | |||

Features

Continuity: Continuous work for 5-10 days to reduce the number of startup times to save fuel.

Energy saving: backburning of combustible waste gas replaces heat source, greatly saving fuel cost.

Large processing capacity: the maximum processing capacity of a single unit can reach 100T per day.

High carbon content: The carbonized material has high carbon content.

Easy to operate: PLC controls data transmission of multiple monitoring points.

Easy installation: Modular design saves installation time and installation costs.