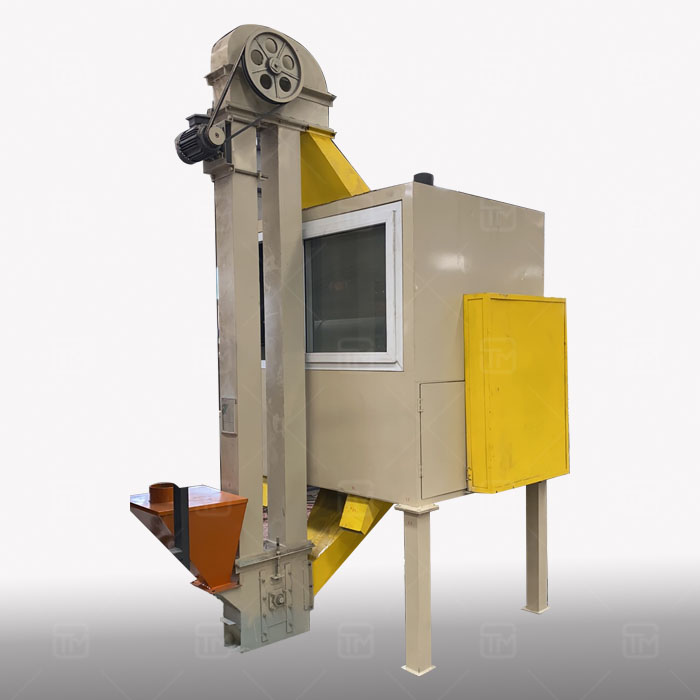

Electrostatic Separator

The electrostatic sorting machine is a device that uses different brands of plastics to generate static electricity differences through heating and friction, and separates 2-5 different types of mixed plastics through electrostatic methods.Electrostatic separators are mainly used in industries such as resource recycling parks, dismantling of waste home appliances, and recycling of waste plastics.

The Range Of Materials

Aluminum plastic sorting of aluminum plastic plates, flexible packaging, aluminum plastic tablet packaging materials, aluminum plastic wires and other aluminum plastic composite materials; copper plastic sorting: sorting of wires and cables, waste circuit boards and bits and pieces, copper plastic pipes and other copper plastic composite materials; other mixed material sorting: metal ore sorting, fly ash decarbonization sorting, slag ash metal extraction, plastic and sand sorting, tea leaf and tea rod sorting, flaxseed fruit and shell sorting, and hair and other material sorting.

Technical Details

Electrostatic separators are devices that utilize the principles of electrostatics to separate or sort materials based on their electrical properties, specifically their conductivity and their susceptibility to being charged. These separators find application in various industries where the separation of mixed materials is required, often in recycling and mineral processing sectors. Here's a brief explanation of how they work and some common applications:

Charging: The process begins by charging the particles in the material mixture. This can be done either by direct contact (triboelectric effect) where particles rub against each other or a charged surface, or by corona discharge where ions generated by a high voltage electrode impart charges onto the particles.

Separation: Once charged, the particles are passed through an electric field created between electrodes. The direction and magnitude of the force experienced by each particle depend on its charge and the polarity of the electric field. Conductive materials lose their charge quickly and may not be deflected as much, while insulative materials retain their charge longer and can be more effectively separated.

Collection: Positively and negatively charged particles are attracted to oppositely charged collection plates or are repelled away from like-charged areas, allowing for their separation.

| Model | Particle Size(mm) | Power(kw) | Dimension(mm) | Weight(Kg) | Drum Diameter(mm) |

| TLS-1000 | 0.01-4 | 3.1 | 1500*1350*3200 | 1000 | 320 |

| TLS-1200 | 0.01-4 | 3.5 | 1800*1500*3500 | 1250 | 320 |

| TLS-1500 | 0.01-4 | 4.6 | 2300*1350*3500 | 2000 | 320 |

| TLS-1800 | 0.01-4 | 4.8 | 2650*1350*3600 | 2500 | 320 |

| TLS-2000 | 0.01-4 | 5.5 | 2700*1600*4300 | 3200 | 320 |

| TLS-2500 | 0.01-4 | 7.5 | 3200*1600*4300 | 3800 | 320 |

Features

1, electrostatic sorting machine feeding device is a key technology for the purity of sorting materials. According to the different materials, our electric separator adopts a unique feeding method, or adopts a separate frequency conversion speed control to feed, so that the material evenly enters the corona electric field and realizes the sorting effect of the material.

2, the two-roll electric separator can realize the metal in the second roll again, improve the purity of the metal.

3, electrostatic sorting machine to achieve the metal in the second roll again, compared with the single-roll electric sorting machine save time and labor, productivity has been improved.

4. Due to the tens of thousands of volts of high pressure generated inside the equipment during work, special attention is paid to personal safety during operation. Even if the machine stops working, there is still a high voltage charge inside the equipment, which brings danger to the staff when they are not careful in operation, so in view of this situation, our company specially designed the automatic discharge function to provide reliable security for the operation of the operator.

5, the equipment in operation for a period of time, the internal will produce a lot of dust, directly affect the sorting effect, my company specially designed dust blowing device, so that the equipment always maintain a good sorting effect.

6, electrostatic separator is the use of stable high-voltage electrostatic power supply, due to the influence of weather humidity or peak hours of electricity consumption, will make the voltage change, high-voltage power supply instability will affect the quality of sorting, my company specially designed automatic voltage regulator, make the high-voltage power stable and unchanged.