Aluminium Plastic Recycle Plant

Aluminum Plastic Separation Machine is used for recovery of waste aluminum plastic materials, can put the aluminum and plastic separation, aluminium plastic separator adopts crushing, grinding, separating, dust removing technology process to achieve completely & simultaneously separating recycling aluminum metal and plastic powder. And the recycled aluminum powder can be sold directly to the aluminum reclamation plants and fireworks and firecrackers plants, the PVC powder also can be sold in the market as the re-process materials.

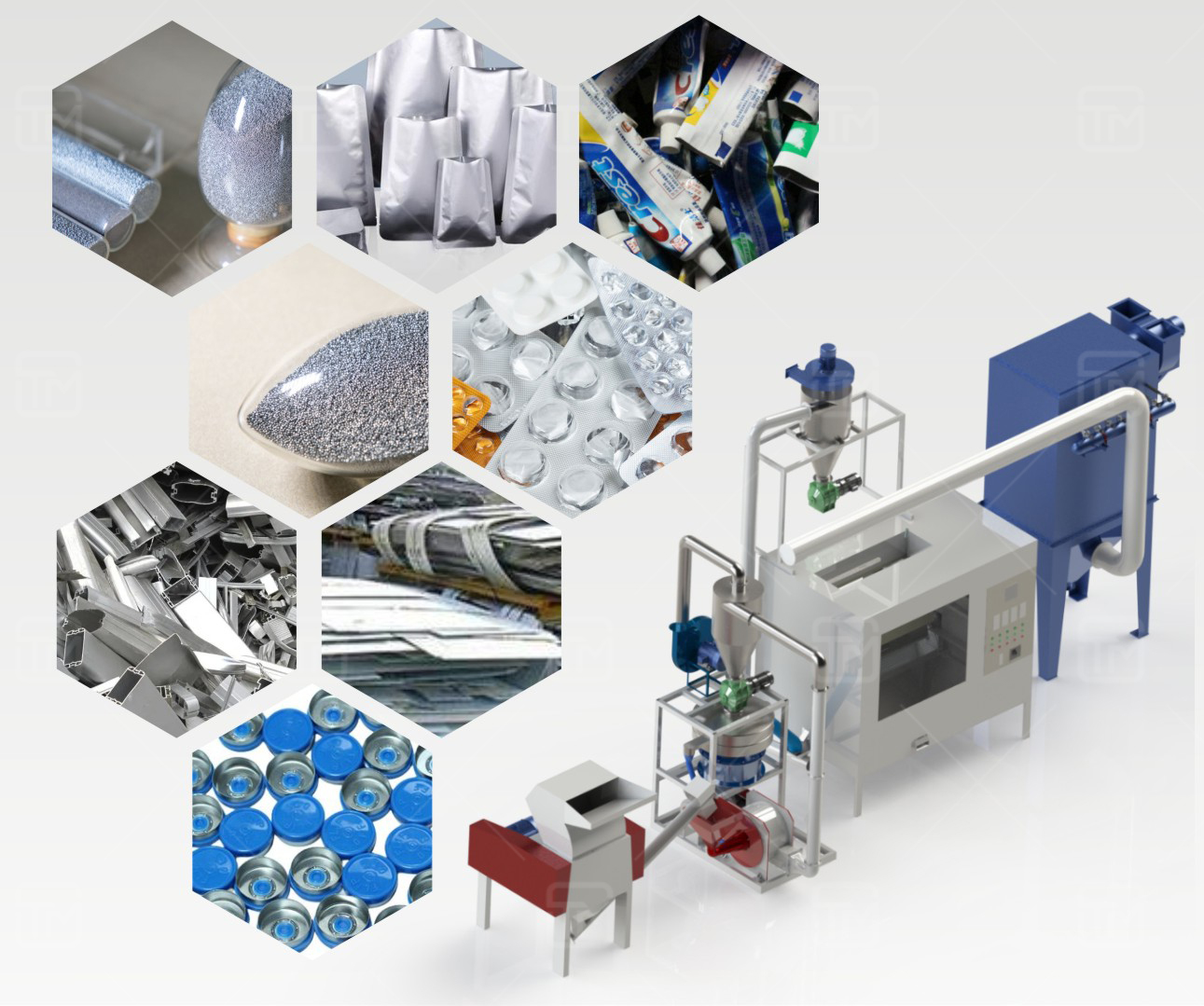

The Range Of Materials

The waste aluminum plastic crushing and sorting equipment is a device that completely separates the aluminum plastic composite material into aluminum and plastic. The raw materials come from the corner scraps of pharmaceutical factories, aluminum plastic board factories, food and beverage plants and other aluminum foil packaging industries, waste soft bags, capsule plates and toothpaste skins in waste stations.

Technical Details

Aluminum plastic recycling production line usually includes the following core links:

Crushing: First, the discarded aluminum plastic material is broken through a crusher to reduce it to a size that is convenient for subsequent processing.

Separation: The crushed mixture requires specific separation techniques to separate aluminum and plastic.

This usually involves several methods:

Dry separation: Initial separation using physical methods such as air separation, vibrating screening or wind separation.

Electrostatic separation: The use of high voltage electrostatic separator, due to the different electrical conductivity of aluminum and plastic, so as to achieve efficient separation.

Friction and vortex separation: The plastic is charged by friction and then further separated by vortex separation technology.

Cleaning: In order to remove impurities and residues attached to the material, there may be a cleaning session.

Drying: After cleaning, the material needs to be dried to ensure that it is suitable for subsequent processing and storage.

Smelting and reshaping: the separated aluminum and plastic are respectively smelted or reprocessed to be converted into reusable raw materials or products.

| Model | Capacity(kg/h) | Power(kw) |

| TLS-300 | 300 | 65 |

| TLS-600 | 600-800 | 125 |

| TLS-800 | 800-1000 | 225 |

Features

1.High automation program, simple operation and stable performance.

2.The separation efficiency of electro-selection is up to 99%, and the finished product can be sold directly.

3.No waste water discharge, real green environmental sorting, no secondary pollution.

4.low power consumption, low noise, small footprint, no dust pollution.

5.Wide range of sorting materials, fast sorting speed.

6.The aluminum plastic sorting and reusing treatment equipment adopts water-cooled and air-cooled turbine mills, which make the material separation more clean and adapt to a wider variety of materials.