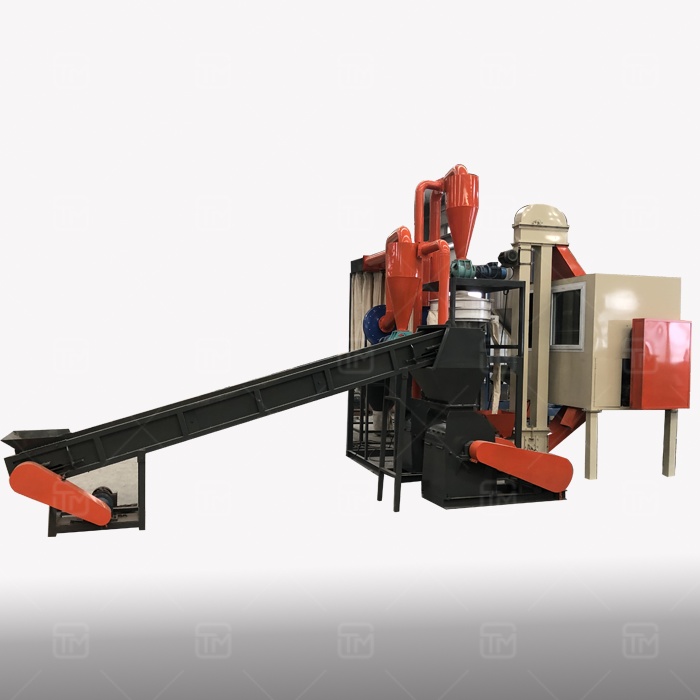

E-Waste Recycling Machine

Printed circuit board recycling machine is a kind of e waste recycling machinery, which is specially designed for separating the precious metals from resin and fiber for recycling use.

Our circuit boards recycling machine adopts advanced physical recycling process, which can help you obtain metal, resin powder and fiber powder from used printed circuit boards. Copper powder and resin fiber powder can be sold directly in the market, therefore, recycling pcbs can not only bring great economic value, but also protect the environment.

The Range Of Materials

Discarded electronic equipment and electrical products, including but not limited to computers, mobile phones, televisions, refrigerators, air conditioners, printers, batteries, etc

Technical Details

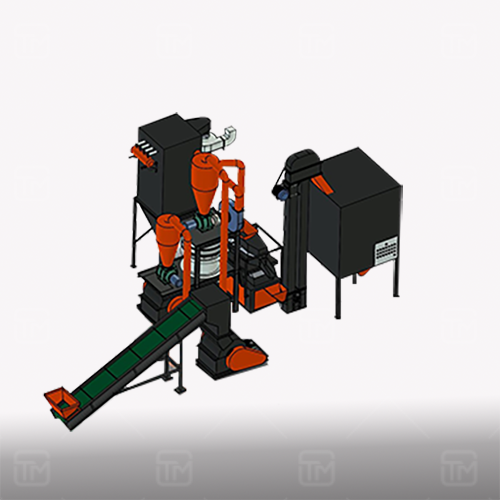

E-waste recycling production lines typically include the following key steps:

Collection and classification: First of all, waste electronic products such as TVS, computers, mobile phones, refrigerators, etc. are collected and preliminarily classified according to type and material.

Disassembly: For large or complex electronic products, disassembly may require manual or mechanical assistance to separate different components and materials.

Crushing: The disassembled material is sent to the crusher where it is broken into smaller pieces for subsequent processing.

Screening and sorting:

Vibration feeder: evenly feed the broken material into the next process.

Magnetic separation: The use of magnetic separator to separate the ferromagnetic metal.

Eddy current sorting: Non-magnetic materials will enter the eddy current sorting machine and separate non-ferrous metals, such as copper and aluminum, through the generated eddy current effect.

Fine particle separation: For finer particles, techniques such as wind separation, flotation, and screening may also be used to further separate different materials.

Purification and refining: The separated metals and other materials are further processed and purified for reuse as raw materials.

| Model | Capacity(t/h) | Power(kw) |

| TPL-300 | 300 | 68 |

| TPL-500 | 500 | 110 |

| TPL-1000 | 1000 | 198 |

| TPL-2000 | 2000 | 385 |

Features

1. High rate of metal recovery;

2. Saving power,saving manpower;

3. Electricity choose separation efficiency is as high as 99.9%, finished products can be directly put on the market;

4. No pollution, due to the pulse dust removal equipment;

5. High purity rate of end-pure copper as high as 97%;

6. PLC system makes it easier to operate.