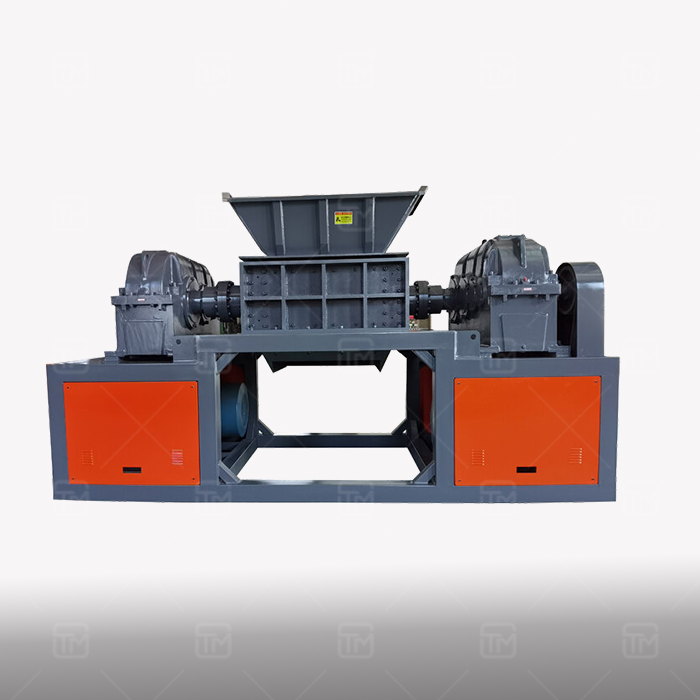

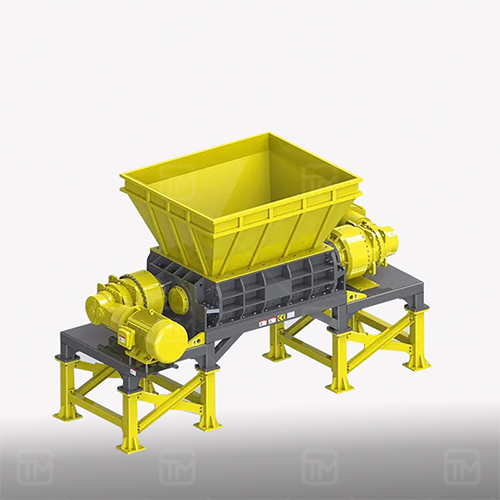

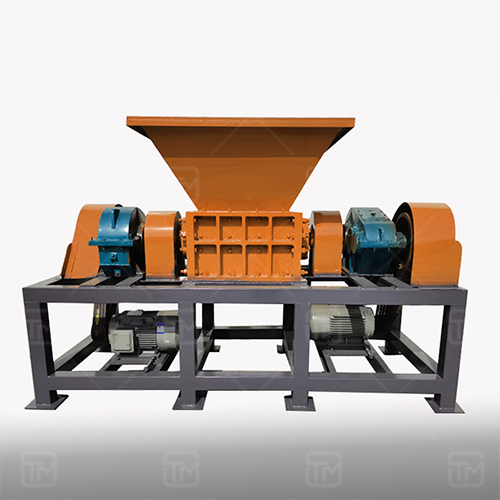

Double Shaft Shredder

Double shaft shredder is a mechanical device that is mainly used to cut or tear large materials (such as paper, plastic, wood, rubber, metal, etc.) into small pieces or fragments. Its working principle is to achieve the crushing of materials by installing a rotary shaft with a sharp blade. The design and size of the shredder will vary depending on the type of material handled and the final size of the debris required. It is widely used in industrial production, waste recycling, garbage disposal and other fields to improve the efficiency of material processing and facilitate transportation, storage or further processing.

The Range Of Materials

Solid Waste: Such as plastic waste (including mixed plastics), rubber, wood, paper, and organic waste.

E-Waste: Electronic waste like computers, TVs, and other electronic devices can be shredded before further recycling processes.

Fiber and Textiles: Old clothes, carpets, and other textile waste can be shredded for recycling or disposal.

Metal Scraps: Light metal scraps, such as aluminum cans, copper wires, and even car bodies, can be shredded for easier handling and recycling.

Tyres: Whole vehicle tires can be shredded into smaller pieces, which are then used for tire derived fuel or further processed into crumb rubber.

Technical Details

| Model | Capacity(t/h) | Power(kw) | Chamber Size(mm) | Blade Diameter(mm) |

| TSS-600 | 0.5-0.7 | 15X2 | 600x480 | 200 |

| TSS-800 | 0.6-1 | 22X2 | 800x480 | 200 |

| TSS-1000 | 0.8-1.5 | 30X2 | 1000x690 | 300 |

| TSS-1200 | 1.2-1.8 | 45X2 | 1200x690 | 300 |

Features

1. It has the characteristics of low speed, high torque and low noise. It is controlled by PLC. It has the functions of starting,stopping, reversing and overloading automatic reversing.

2. The motor + reducer drives the cutter shaft to achieve the shearing effect of low speed and high torque.

3. Bearing six-fold seal, effective waterproof and dust-proof, prolong the service life of bearings.

4. After tool wear, the repair technology of tool coating and welding is adopted to realize the repeated use of the tool, which greatly reduces the maintenance cost of the tool.

5. Separate box design, can easily and quickly remove the entire axle (axle, blade, bearing, sealing system).

6. Tools are arranged according to helix to achieve high efficiency cutting.

7. Both the inner hole and the spindle face of the cutter are designed in hexagonal form to realize the uniformity of the force exerted on the cutter.

8. According to different materials and product shapes to be torn up, different types of cutters can be selected.