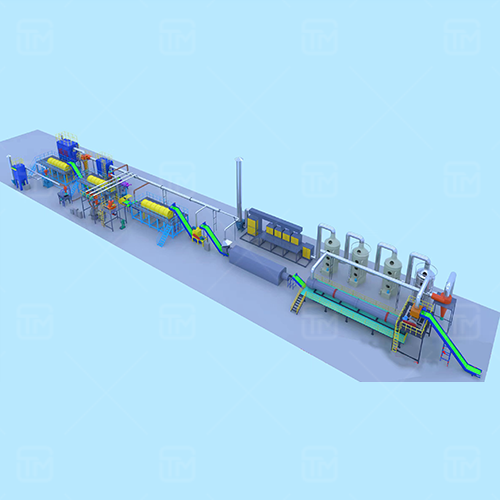

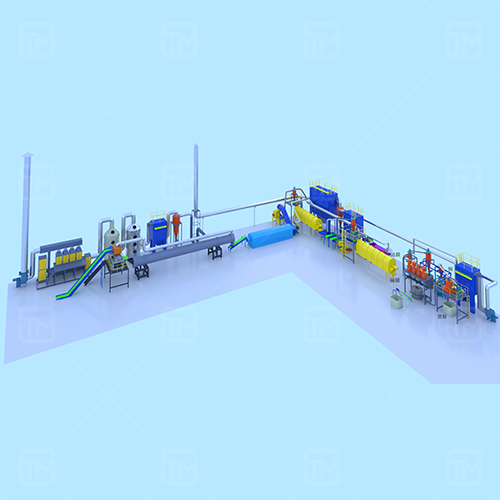

Lithium Ion Battery Recycling Machine

Waste lithium battery recycling equipment is mainly used for mobile phone lithium batteries, power lithium batteries, soft pack lithium batteries, hard shell lithium batteries and other lithium batteries for crushing, sorting and recycling, can achieve copper, aluminum, iron, diaphragm, plastic, positive and negative materials classification and recycling, separation clarity can reach more than 95%, recovery rate can reach more than 99%. The production line is composed of crushing system, sorting system, conveying system, air purification system, automatic control system, etc., equipped with a central dust removal system, the production process is free of exhaust gas and dust.

The Range Of Materials

Lithium iron phosphate battery, ternary lithium battery, lithium cobalt acid battery, lithium manganese acid battery, polymer, cylindrical lithium battery, square lithium battery, power battery, mobile phone lithium battery, positive and negative electrode sheet, etc

Technical Details

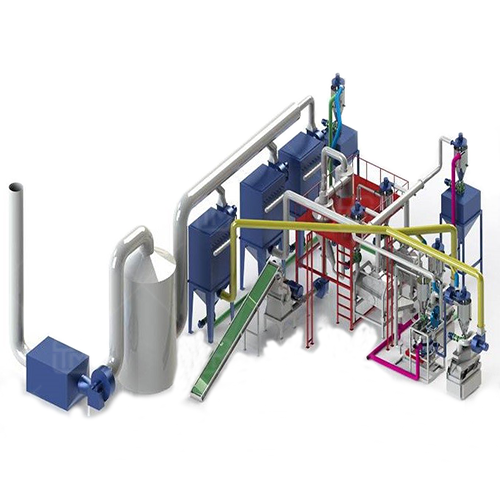

The lithium battery recycling plant consists of multiple machines working together, the following is a description of some of the core equipment:

Shredder: Shredded lithium batteries into smaller pieces.

Hammer crusher: For the secondary crushing of shredded materials.

Grinder: For the grinding of the crushed materials.

Separation Machine: Separate the materials after being ground.

Collector: Collect and release the dust .

Pulse Purifier (Air Cleaner): Clean all the dust produced during the operation of the whole system.

Classifying Screen: Screen the materials sorted by the separation machine, and screen out of large metal materials.

Magnetic Machine: Separate nickel from the metals.

Gravity Separator: Separate those finer materials got from the screening machine and separate the metal completely.

High-pressure blower: Keep the whole system in a negative state so as to collect the materials and purity the air.

| Model | Capacity(t/h) | Power(kw) |

| TLB-300 | 300 | 144 |

| TLB-500 | 500 | 225 |

| TLB-1000 | 1000 | 311 |

| TLB-2000 | 2000 | 595 |

Features

1.Through the combined process of hammer crushing, vibrating screening and air separation, the resource utilization of metal copper and toner in waste lithium battery materials can be realized.

2.The material can be effectively separated from the toner and the copper foil by the hammer vibration crushing, and then the copper foil and the toner can be initially separated by the vibration based on the size difference and shape difference between particles.

3.For the broken particles with a particle size of 0.125~0.250 mm and low copper grade, the effective separation between copper and toner can be achieved by air separation, and the good recovery effect can be achieved when the air speed is 1.00 m/s.

4.The equipment is mainly used for lithium-ion battery manufacturers to separate aluminum and copper mooring from positive and negative materials in scrap positive and negative films for recycling purposes. The complete set of equipment operates in the negative pressure state, no dust leakage, and the separation efficiency can reach more than 90%.