A Magic Machine To Reshape Scrap Iron And Aluminium

The emergence of metal crusher is an innovation in the treatment of scrap metal. In the past, a large number of waste metals were piled up, which not only occupied valuable land resources, but also caused potential pollution threats to the environment. Now, with the help of metal crushers, these seemingly useless scrap metals can be revived.

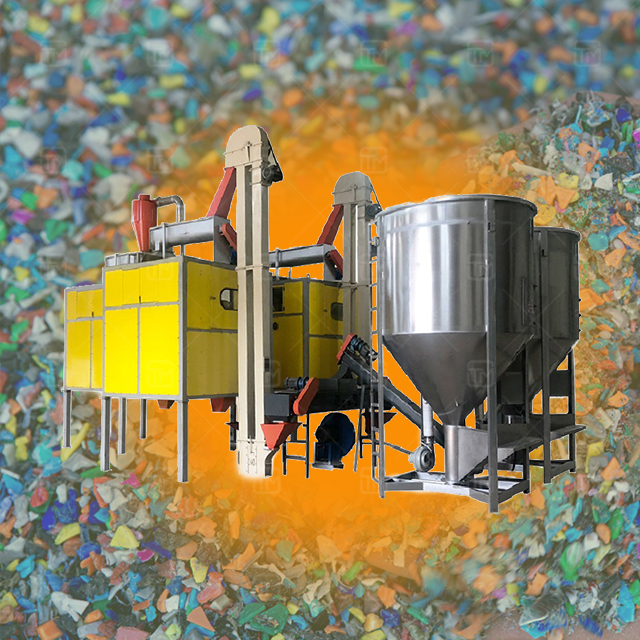

The way it works is full of ingenuity. A powerful power system drives a robust crushing tool that quickly crushers scrap metal of all shapes and sizes into small, uniform pieces. This process may seem simple and crude, but it contains precise control and efficient energy conversion. Each crushing is a re-shaping of metal materials, making them from disorder to order, laying a solid foundation for subsequent processing and reuse.

The advantages of metal crusher are too numerous to list. First of all, it greatly improves the efficiency of waste metal treatment. Dismantling, which used to take a lot of manpower and time to complete, is now done in an instant with the roar of machines. Secondly, the volume of the broken metal is reduced, which is convenient for transportation and storage, and reduces logistics costs. What's more, the metal materials that have been crushed have a more uniform texture and higher purity, which makes them better able to function when they are put into production again, improving the utilization of resources.